Kakaretso ea Sehlahisoa:

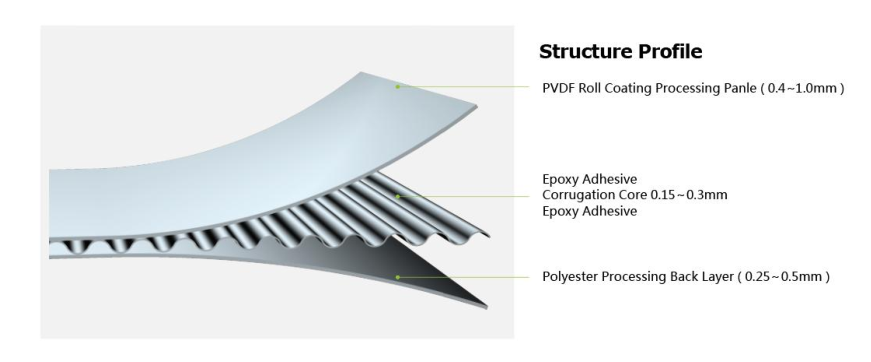

Aluminium Corrugated Composite Panel e boetse e bitsoa aluminium corrugated composite panel, e sebelisa AL3003H16-H18 aluminium alloy material, e nang le sefahleho sa aluminium botenya 0.4-1.Omm, botenya ba aluminium bo ka tlase 0.25-0.5mm, botenya ba mantlha 0.15-0.3mm. moleng o tšoanang oa tlhahiso, o sebelisa thermosetting dual structure resin e khomarela sefahleho le aluminium e ka tlase ka sebōpeho sa arc, eketsa matla a ho khomarela, ho ba le liphanele tsa tšepe tse ntle haholo.

Aluminium Corrugated Composite Panel e sebetsa lekhetlo la bobeli:

> ho poma

- Aluminium Corrugated Composite Panel cutting e lokela ho sebelisa mochini o khethehileng oa ho itšeha, o sehiloeng ho latela boholo bo hlophisitsoeng ka mor'a ho lokisoa sethaleng se bataletseng.

- Sebaka sa ho itšeha se lokela ho ba se setle haholo ebile se hloekile.

> Ho thothomela

Mokhoa oa bohlokoa oa ho sebetsa Aluminium Corrugated Composite Panel ke

grooving 0.15-0.2mm ka tlase aluminium.Processing angle kgothaletswa ho etsa

aluminium e ka tlase le konokono e entsoeng ka masenke hammoho ka angle ea 91 degree.

1) Sakha ea ho sebetsa e tšoana le setšoantšo se bohareng se ka tlase.Sebelisa sakha e nang le R5.5 le angle 91.

tekanyo.

2) Bakeng sa grooving e kholo, sebelisa grooving saw setšoantšong le mechenical e tsamaeang

lisebelisoa ho ntlafatsa katleho ea tlhahiso.

Grooving: ho latela moralo oa ho taka, mekhoa e khutlang e lokela ho khaola

ho latela setšoantšo se letšehali.

> Ho bopa

- Ho bopa ka mor'a ho korotla, lokisa sehlahisoa sethaleng se itseng se bataletseng, kobeha angle ea 90 degree ka clamp e kobehang ho latela chate ea moralo.

-Karolo ea sekhutlo ea ho kobeha e tlameha ho otloloha (ho elelloa hore ho thibela ho robeha ha lera la sekhutlo, mosebetsi o tlameha ho sebetsoa ka holimo ho 10°C.

- Bophahamo bo kobehang ba bonyane limilimithara tse 20 ka holim'a moeli oa moralo, karolo ena ea Angle e nang le silika ea silika e ka fihlela phello e ntle ea ho thibela metsi le lisebelisoa tse ling.)

> Roll Circle

- Li-degree tsa arc tsa ho sebetsa lihlahisoa, sebelisa poleiti e tloaelehileng ea lirolara tse tharo.

-Ho sebetsa lihlahisoa tsa arc ho boloka 100 mm e qala joalo ka benchmark.

- Ha o thetheha, ha o khone ho emisa.

- E lokela ho ela hloko tataiso, tsamaisa arc ea mabili le boto ea mantlha ka lehlakoreng le otlolohileng.

> Tsebiso Bakeng sa Grooving

A) Ho kobeha habeli le ho seha boemo bo sa tsitsang

-Ho tlosa 0.15-o.2mm ho tloha ka ntle lakane nakong ea grooving.

-Bending clamp ha e kenye flange botebong bo lekaneng. sisinya ho kenya clamp ka har'a flange ka bongata.

- Ho hloka setsebi se nang le boiphihlelo, etsa tlhahiso ea ho sebelisa setsebi sa litsebi

- Ho se leka-lekane ha khatello ea mochini oa grooving ho etsa hore karolo e kobehang e se lekane, fana ka maikutlo a ho boloka khatello ea ts'ebetso ea mochini e tsitsitse.

B)matla a konokono a hlobola sefahlehong

-Ha o bona sesosa sa ho ebola, ka kopo, hlahloba sehiloeng sa saw pele se sebetsoa.

-Ha u notlela, u se ke oa tšela mola o bohareng oa grooving, ho seng joalo phello ka mor'a ho kobeha e ke ke ea kopana le tlhokahalo ea moralo.

Kopo: